Preventive Vs Predictive Maintenance – the Performance Gap

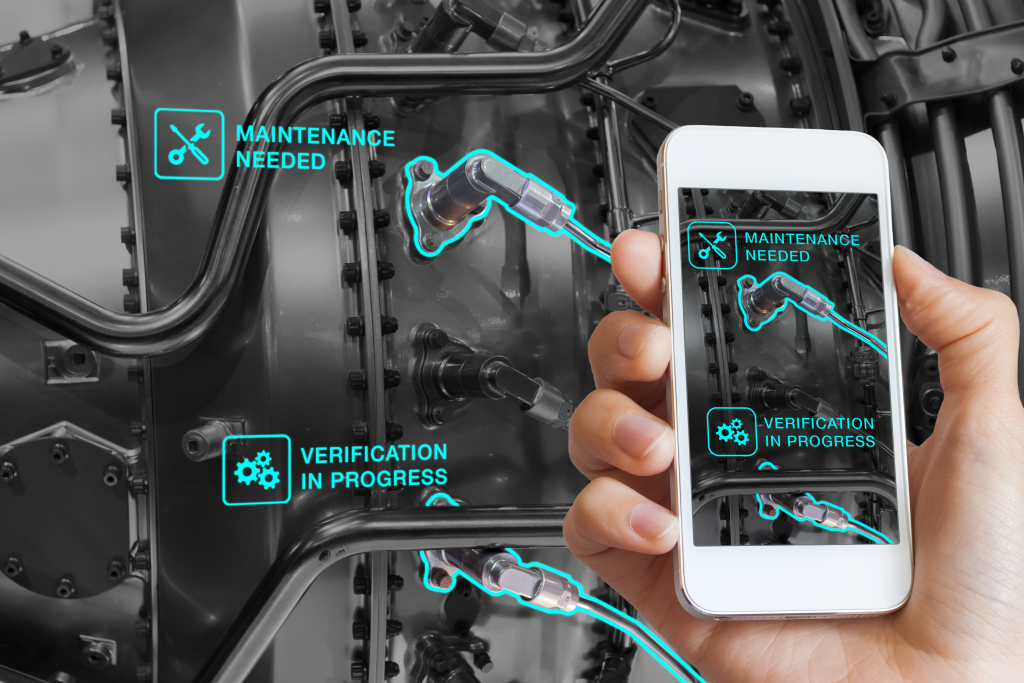

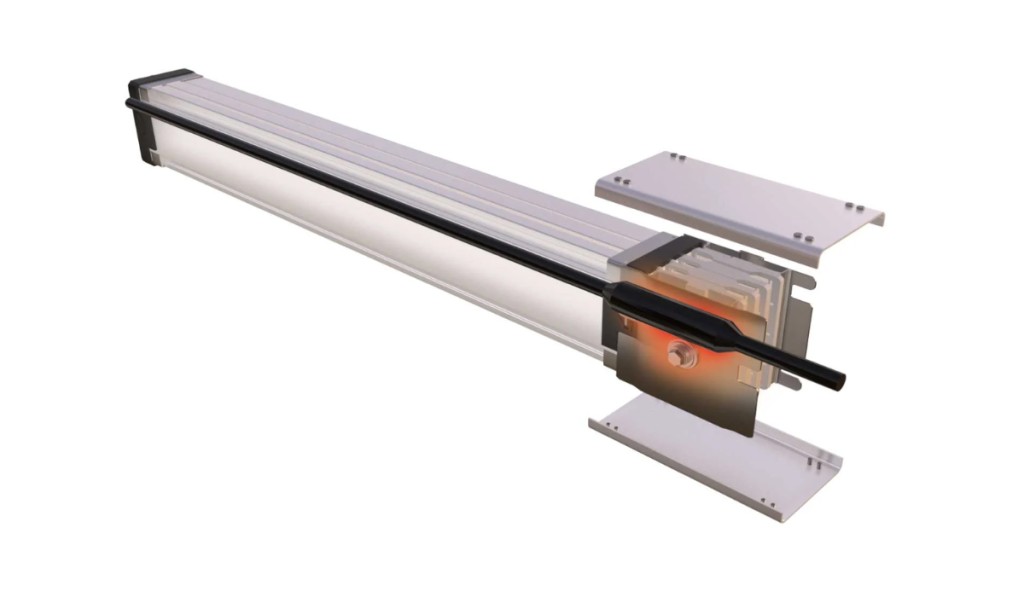

One of the most common causes of power outages and a primary cause of electrical arc flash incidents is the rise in the temperature of a faulty joint or connection. As equipment ages, faulty electrical connections in LV/MV switchgear, and other electrical equipment can increase; studies show that poorly maintained switchgear is 62% more likely to fail.It gives users a call-to-action on a specific joint which is potentially faulty and needs attention before a more serious problem occurs.

Preventive Vs Predictive Maintenance – the Performance Gap Read More »