Dry Transformers

24×7 Thermal Monitoring of critical Dry Resin Core Transformer connections

Permanent and Predictive Thermal Condition Monitoring for Cast Resin Core Transformers

Datacenters

Oil & Gas

Finance

Healthcare

Datacenters

Mining

Marine

Petrochemical

Dry Transformers are extremely critical to the integrity of the electrical distribution, if the transformer fails then it is highly likely that the entire infrastructure will suffer an electrical outage, which is costly in both down time and repair costs.

Exertherm is the World No.1 for 24×7 Thermal Condition Monitoring. Our solution is specifically designed to provide continuous thermal monitoring for Dry Resin Core Transformers, utilising our IR Sensors to monitor critical connectors on both Low Voltage and High Voltage sides.

We protect your electrical assets from costly outages while increasing safety via remotely monitoring equipment, increasing asset integrity and minimizing downtime.

Exertherm™ is the next technology step from periodic thermal imaging inspections and provides significant & tangible benefits over traditional periodic thermal inspection…

Protect your electrical infrastructure from outages with Exertherm 24×7 Thermal Condition Monitoring.

Protect your electrical infrastructure with Exertherm 24×7 Thermal Condition Monitoring.

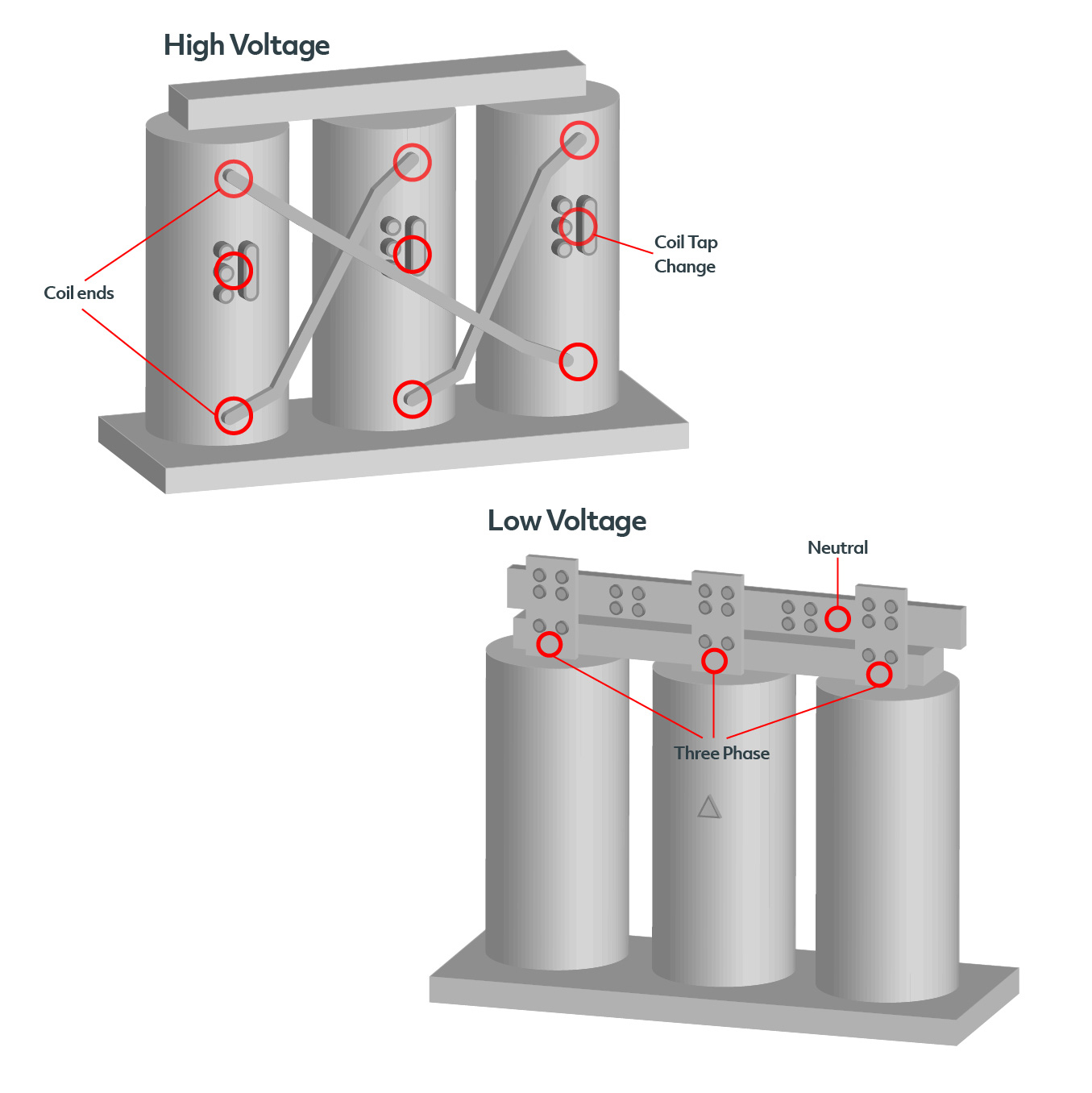

For High Voltage:

- IR Sensors continuously monitor both ends of each coil

- IR Sensor also continuously monitor coil tap connections

For Low Voltage:

- IR Sensors continuously monitor the three phase and neutral

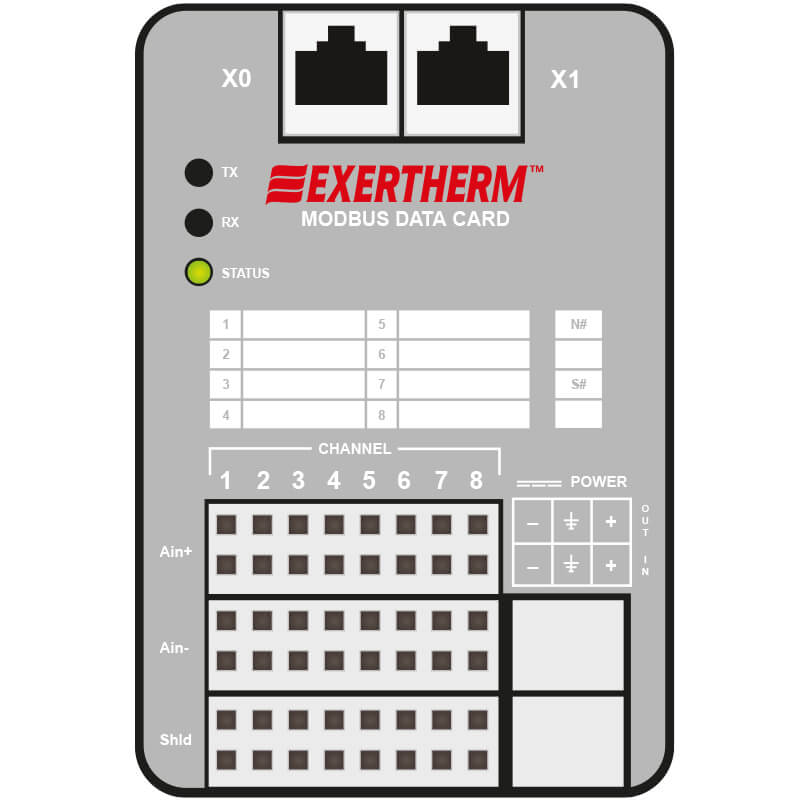

IR Sensors then connect back to the Exertherm Modbus Datcard, which collects and transmits the Sensor temperature data, and activates alarms when a fault is detected.

Features

PERMANENTLY INSTALLED SENSORS

THE ONLY NON-CONTACT & NON-POWERED BUS MONITORING SOLUTION

RELIABILITY WITH A LIFETIME GUARANTEE

REAL TIME DATA 24X7 / 365

SUITABLE FOR NEW BUILD OR RETROFIT

OEM VENDOR NEUTRAL

Benefits

INCREASED OPERATIONAL UPTIME & RELIABILITY

INCREASED FACILITY & OPERATOR SAFETY

REDUCED RISK OF FIRE/EXPLOSION RESULTING FROM ARC FLASH

REDUCED UNPLANNED MAINTENANCE

NO FUTURE INSPECTION DOWNTIME

COST SAVINGS FROM REDUCED OUTAGES

Why Exertherm?

Exertherm® is the global number one provider of 24×7 Thermal Condition Monitoring for electrical infrastructure, successfully installed worldwide by all major OEMs. We deliver complete solutions for LV/MV Switchgear, MCC Drawers, Dry Transformers and more. We’re so proud of our proven reliability we even offer a zero maintenance lifetime guarantee.

World No.1 Thermal Condition Monitoring Solution with Proven Reliability

Zero Maintenance & Lifetime Guarantee on Sensors

Complete Thermal Monitoring Solution for LV/MV Bus, Cable, MCC + TX

Sensors providing accurate data of uniform quality are a key part of the IIOT jigsaw - no sensors = no data

Wireless sensors pose a potential hacking threat to critical infrastructure. Exertherm is hardwired, and thus avoids any potential hacking issues.

Exertherm solutions are accepted & have been successfully installed in major projects globally by all major OEMs.

Product

1 – IR Sensor

For busbar temperature monitoring

2- Exertherm Modbus Datacard

Collects data from 8 x IR / EM Cable sensors

3 – ARM XL

Panel mounted HMI

1

2

3

Connectivity

There are two connectivity options available:

Raw Data Transfer

Modbus RS485: Exertherm Datacard direct to BMS/SCADA Via converter TCP/IP to BMS/SCADA

Exertherm® ARM XL HMI

Local graphics on HMI & status LED + local/remote alarms + transfer of raw data via Modbus TCP/IP.

Global OEM Approval

24×7 Thermal Protection

Zero Maintenance

Lifetime Guarantee

Simple Installation